Impact Test

The notch impact test supplies information about the toughness, brittleness and aging resistance of a material. The experimental procedure is as follows: A material specimen is notched on its backside. A swing hammer with a standardised kinetic energy impinges on the specimen. This is subjected to bending forces and strongly deformed or crashed. The swing height, which the swing hammer reaches on the other end of the material, is then displayed on the unit and delivers an exact measurement of the notch-bar impact work. The notch impact test can be executed in the environment of different temperatures.

Bulging Test

The bulging test is a process to examine the deformability and crack resistance of pipes. For that, the tester drives a conical test piece in the end of the specimen until it has been expanded up to a statutory value. The test conditions are fulfilled if no cracks are shown.

Flattening Test

The flattening test serves to verify macroscopic internal and external detriments in pipes and tracks down defective welding seams. For that, a pipe section is folded between two panels either until it reaches the required level or until it breaks. The testing conditions are met if the specimen is free from cracks. Alternatively, the flattening test provides information about the formability.

Bend Testing

Bend tests are performed in various arrangements the best known of which are the 2-point, 3-point and 4-point bend tests. They are used to find out about several strength values such as the flexural strength, the elasticity and the deformability. Bend tests are carried out with constant speed up to a pre-set bending angle or until the breaking load is reached.

Tensile Testing

For tensile tests, a material specimen is suspended to a slow, uniform and shock-free elongation up to breakage. Next to the elongation at break, the material reveals other important characteristic values such as its yield point, tensile strength and the reduction of area. For metallic test objects, the standards EN ISO 6892-1, ISO 6892, ASTM E 8, ASTM E 21, DIN 50154 and DIN 50125 apply.

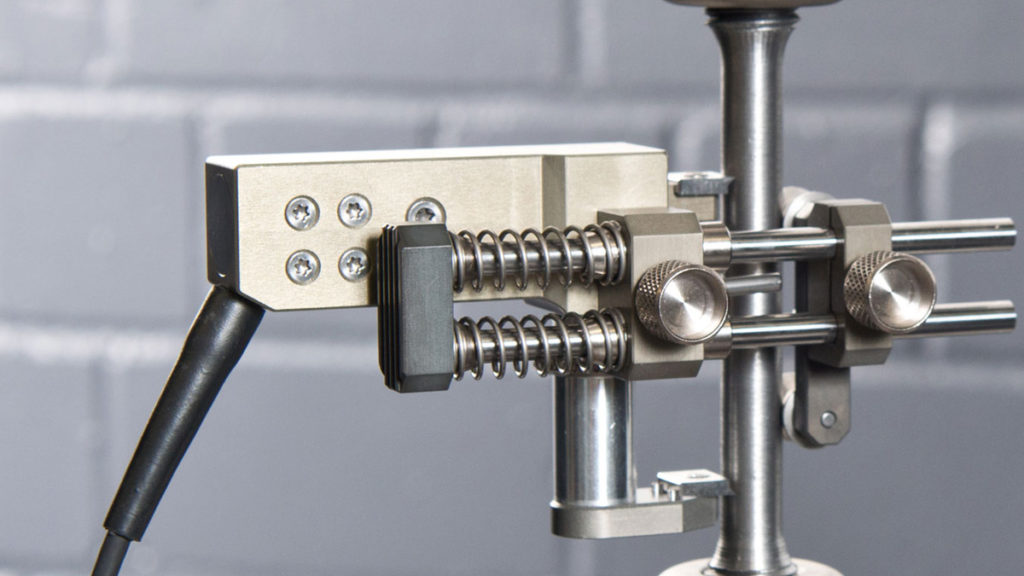

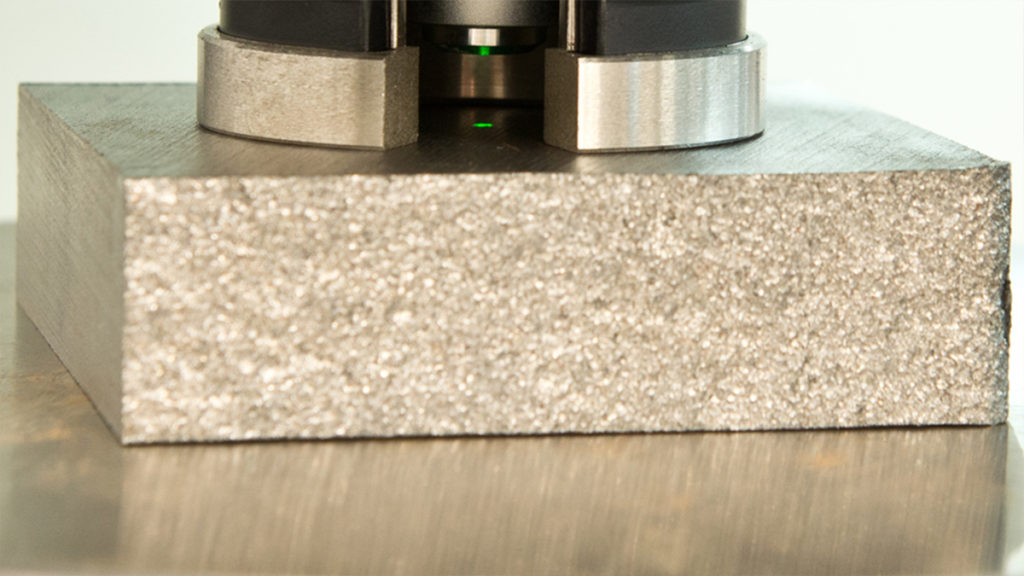

Hardness Testing

How a material presents itself under loading influence provides important information about its mechanical characteristics and its abrasion. Our experts execute hardness testing on surfaces and components both mobile and stationary. By doing so, a measurement is determined which describes the resistance to penetration of a standardised test piece. The common testing processes for the measurement of hardness are based on the depth of penetration of various test pieces.